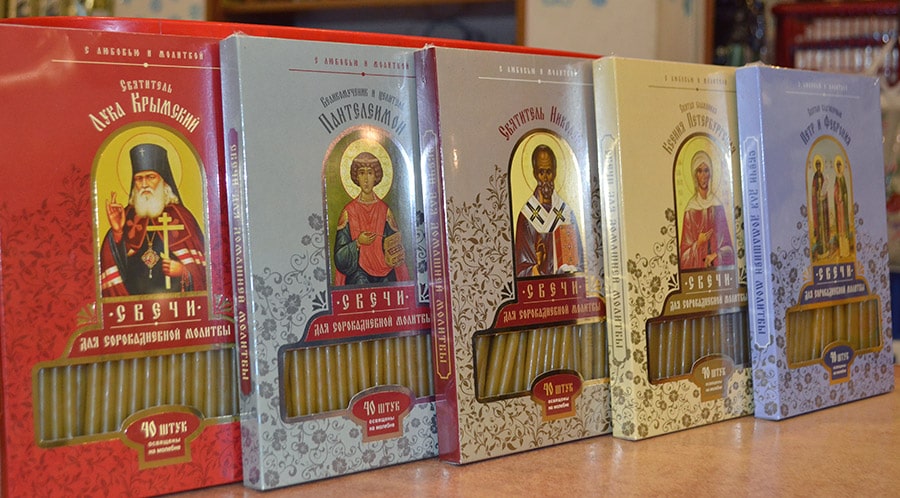

The candle production workshop was opened less than one year after the Convent was established. In the beginning, production volumes remained small, and the processes relied extensively on menial labour and makeshift equipment. The workshop itself is located in one of the Convent’s basements. However, the workshop was making fine products of excellent quality. The product line included luxury candles (designed by one of the workshop’s first directors Brother Victor Shulga) and prayer candles.

Today, the workshop is the largest maker of prayer candles in Belarus. It is located in the monastic farmstead/rehabilitation centre for men.

The workshop is still one of the few remaining producers that continues to make wax-only candles. Its workers are seven brothers and sisters under the direction of Sister Svetlana. The days before the feast of the Meeting of Our Lord Jesus Christ is one of its most busy periods - the production process continues day and night. The weeks before the Pascha are also busy. Red candles become highly popular at that time. We only use naturally sourced pigments of food or cosmetics grade.

The work of the operators is physically demanding and requires a lot of stamina and fitness. The temperature in the workshop is at least 30 degrees. The work involves lifting heavy weights and being around molten wax.

The process starts with the selection of the right type of wax. The wax is loaded in a container of stainless steel and heated with boiling water until it becomes pliable. It is important not to miss the right temperature point to avoid overheating.

To produce a large batch of large-sized candles we use wax containers bound in candlewick serving as a fuse. It is important to do it right so that the candle does not burn out too early. The thickness of the fuse depends on the size of the candle. In general, larger candles have thicker fuses. The workpiece is transformed into a candle in a series of immersions. With each new immersion, the candle gains weight and acquires its habitual form. After each immersion, the workpiece is taken out and allowed to cool. Afterwards, the process is repeated. For some candles, up to forty repetitions may be needed. Each new immersion should be done with great care and attention, checking that the wax layers build up evenly and the length of the candle is not exceeded.

On average, making a candle of the smallest size requires five immersions. It takes about half an hour to produce a full batch of candles 5 - 6 mm in diameter at the base. Making a batch of the thickest candles, of 22.5 mm in diameter, takes about three hours. In future, we expect our productivity to increase drastically when new equipment has been delivered and installed. We expect this to happen very soon. At full capacity, a modern automated production line can make as many candles in an hour as we are now producing in an entire shift.

In addition to materials and production volumes, another important aspect of the workshop’s success is the attitude and morale on the shop floor. The candles have a life. Material behaviour is very sensitive to changes in the moods and attitudes of the workers. Most workers believe that good candles cannot be made when the team members are arguing or raising their voice at one another. A high proportion of the candles will have defects and imperfections. A calm and prayerful atmosphere on the shop floor is therefore essential. Other vital ingredients to good quality and seamless production processes are a positive attitude and the prayer rule. All of these are important aspects of our contribution to the worship service, the light of a candle that has so much meaning.